AI Automation in Manufacturing

Manual processes are slowing you down? AI-powered automation can streamline operations, reduce errors, and give you a competitive edge.

AI Automation Company for Manufacturing

We help manufacturers automate order management, inventory tracking, quality control, and supply chain workflows. Our AI solutions boost efficiency, accuracy, and speed while reducing costs.

40%

Faster Booking Confirmations

20%

Boost in Repeat Bookings

25%

Reduction in Customer Support Load

30%

Increase in Customer Engagement

Manual manufacturing processes lead to production delays, inefficiencies, and higher operational costs.

AI Automation Services for Manufacturing

Automate the entire order-to-production cycle - from order intake, inventory checks, production scheduling, to shipping notifications using AI agents and workflow tools like n8n.

Implement AI-driven inventory management solutions that optimize stock levels, automate reordering, and provide real-time visibility into inventory status.

3

Quality Control Reporting

Use AI to analyze production data, identify defects, and generate quality control reports automatically - reducing manual inspection time.

4

Procurement & Supply Chain

Streamline procurement processes by automating supplier communications, order placements, and delivery tracking with AI-powered workflows.

5

Machine Monitoring & Alerts

Deploy AI agents to monitor machine performance, predict maintenance needs, and send real-time alerts to technicians before breakdowns occur.

6

Customer Communication

Enhance customer service with AI chatbots and voice assistants that handle order inquiries, provide shipping updates, and manage support tickets 24/7.

Benefits of AI Automation for Manufacturers

Save Time & Reduce Errors

Automate repetitive tasks like data entry, order processing, and reporting to free up staff for higher-value work and minimize costly human errors.

Scale Easily

AI agents can handle increasing workloads without the need for additional headcount, allowing your operations to scale efficiently.

Boost Accuracy

AI-driven workflows ensure consistent execution of processes, improving accuracy in order fulfillment, inventory management, and quality control.

Improve Customer Experience

AI chatbots and voice assistants provide instant responses to customer inquiries, enhancing satisfaction and loyalty.

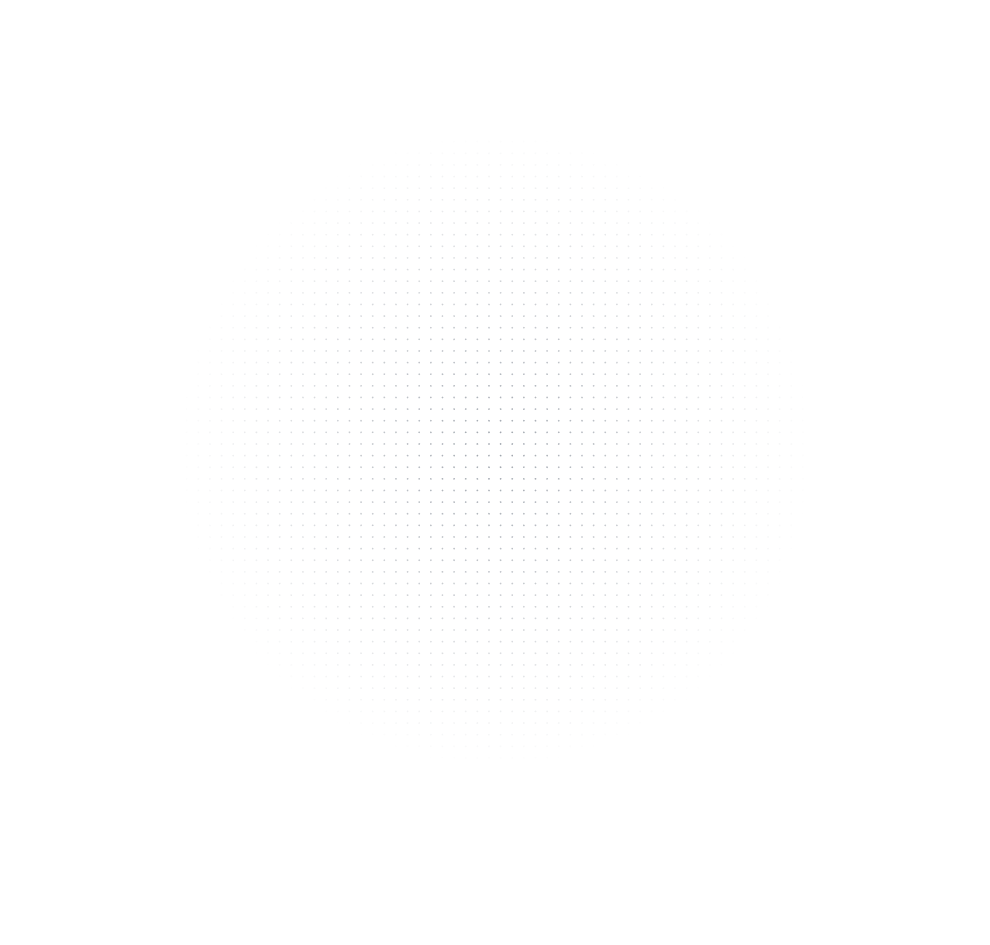

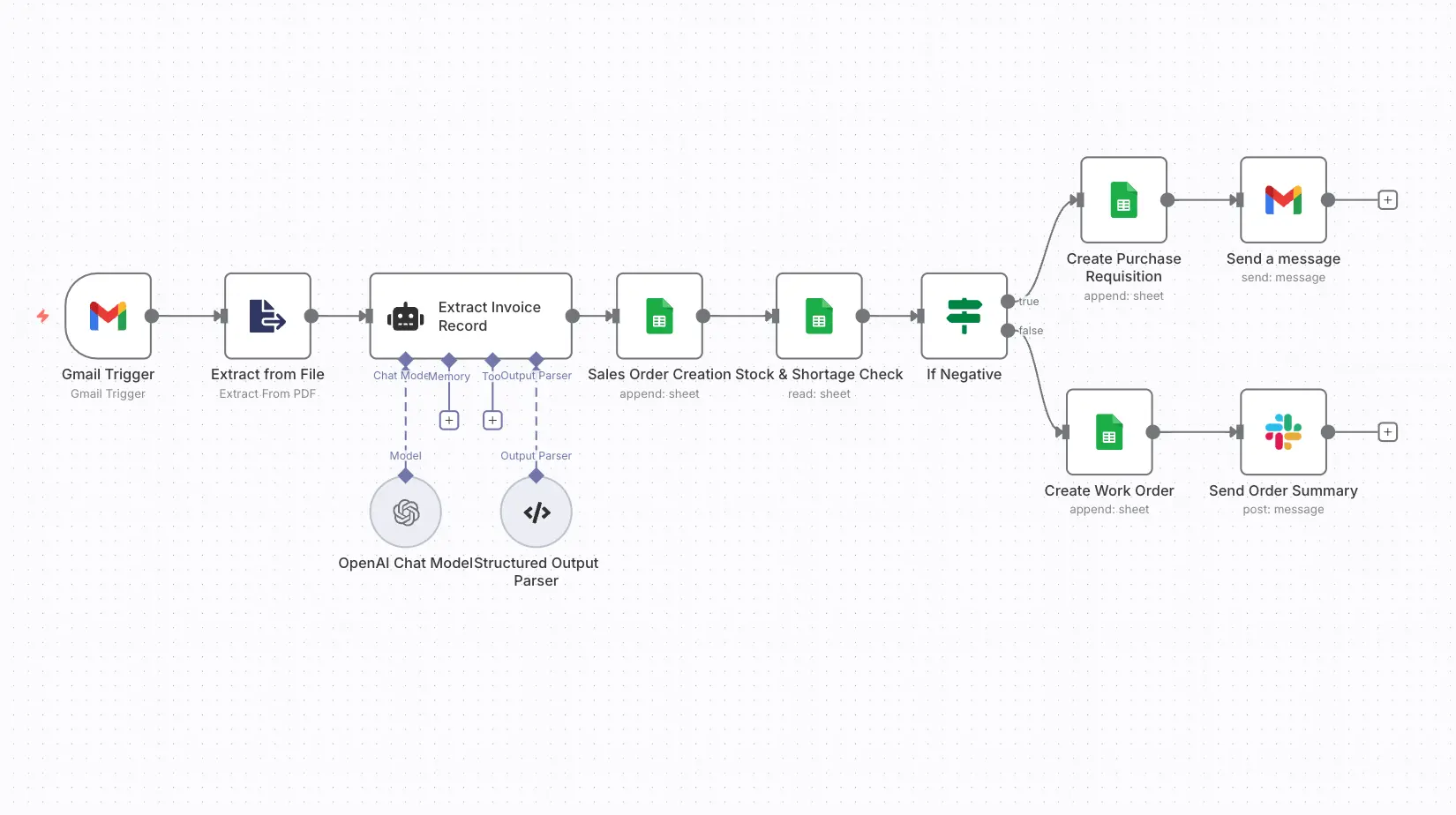

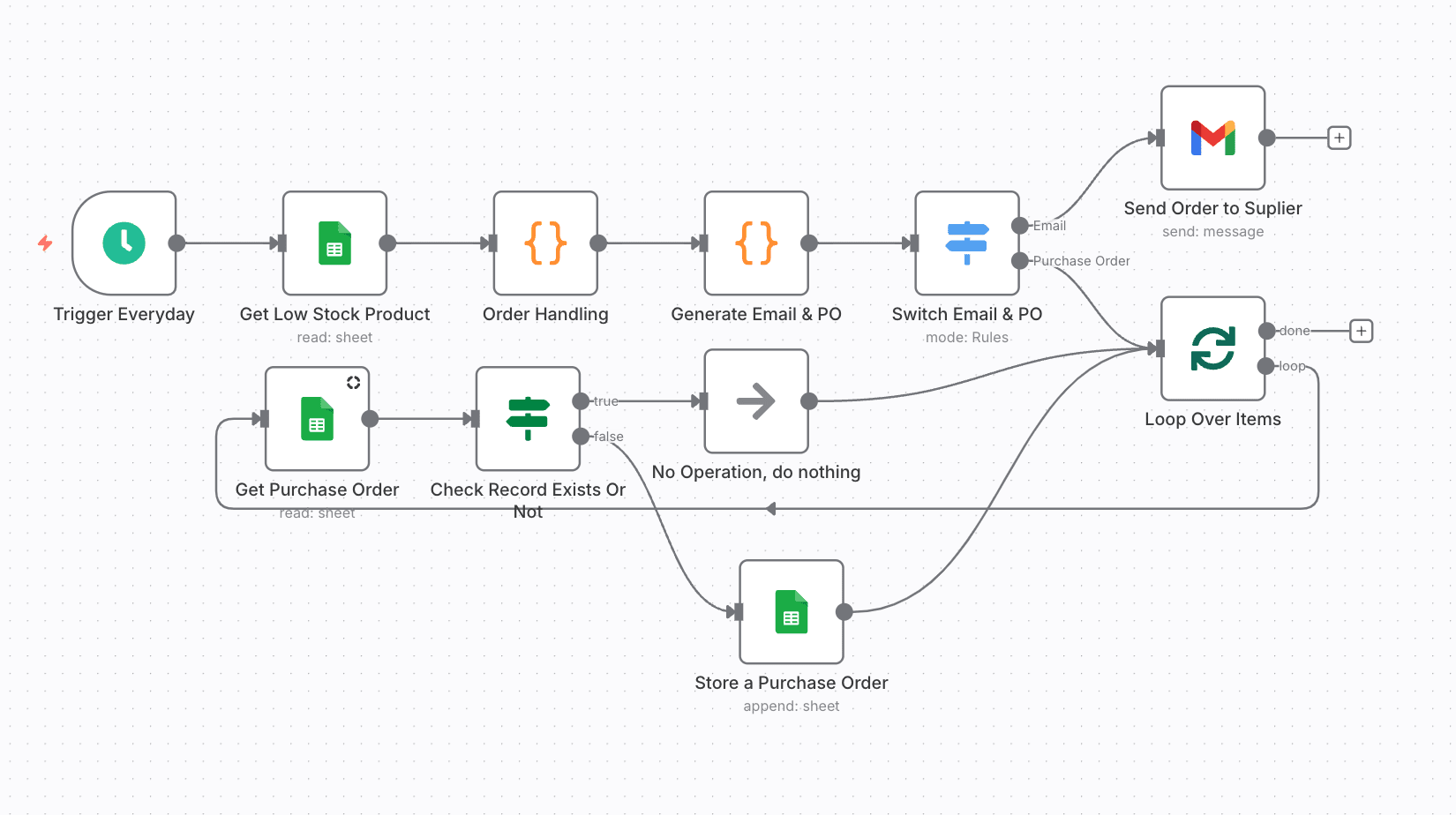

Sample Automation Workflows for Manufacturing

Explore some of our successful AI automation projects that have transformed manufacturing operations.

Manufacturing

Order-to-Production Automation

Manufacturing

Smart Inventory Optimization & Replenishment Process

Manufacturing

Supplier Invoice Processing

Technologies We Use

Supabase

Odoo

Slack

OpenAI

ChromaDB

n8n

Airtop

Zoho

Firecrawl

Hubspot

Twilio

SerpApi

Why Choose InfyOm for Manufacturing AI Automation?

Proven Expertise

With years of experience in AI and automation, we understand the manufacturing landscape and the challenges you face.

Industry-Focused Solutions

We design AI agents and workflows specifically for manufacturing processes, ensuring maximum impact and ROI.

Flexible Integrations

We integrate seamlessly with your existing ERP, CRM, and other systems to create a unified automation ecosystem.

Trusted by Businesses Worldwide

Our clients range from small manufacturers to large enterprises, all benefiting from our AI automation solutions.

Testimonials

It was a wonderful experience working with InfyOm Technologies. They have delivered the app as per my exact needs with a pixel perfect design. I highly recommend them.

Chris Pothecary

Mitul and his team were great! Always open and willing to work on anything I ask. His team regularly offers input on how to improve requests.

Frederick Safyanov

Simply sublime in delivering the requirements for front end and back end. Mitul really knows his staff as works in a collaborative manner.

Rene Muhire

Frequently Asked Questions

What processes in manufacturing can be automated with AI?

AI can automate order-to-production workflows, inventory tracking, quality control reporting, predictive maintenance, procurement approvals, and compliance documentation.

How does automation reduce downtime in manufacturing?

Through predictive maintenance, AI monitors machine data in real time and alerts teams before failures occur, reducing unplanned downtime.

Is automation affordable for small and mid-sized manufacturers?

Yes. SMEs often see the highest ROI because automation helps them cut costs and scale without hiring more staff.

Can AI integrate with existing ERP or MES systems?

Yes. Our solutions integrate with leading systems like SAP, Oracle, Odoo, Microsoft Dynamics, and custom-built platforms.

What impact does automation have on production speed?

Automated workflows reduce manual delays and accelerate processes, often improving production speed by 20–30%.

How does AI improve quality control?

AI analyzes product images and sensor data to detect defects instantly and generate real-time quality reports.

Will automation replace factory workers?

No. It reduces repetitive manual work, allowing workers to focus on higher-value tasks like problem-solving and innovation.

How soon can manufacturers see ROI?

Most manufacturers see savings within 6–12 months from reduced downtime, lower scrap rates, and faster throughput.

Does AI help with compliance reporting?

Yes. AI automates data collection and reporting, ensuring consistent compliance with industry and safety standards.

Can automation scale as production grows?

Absolutely. AI workflows are designed to scale with production, ensuring efficiency even as order volumes increase.

Don’t let competitors outpace you.

Manufacturers who automate today will dominate tomorrow.